Country:

México

Sector:

Manufacture

Size of the company

Medium (100 to 500 employees)

Euwe Eugen Wexler from Mexico, a company with sights on excellence in customer service

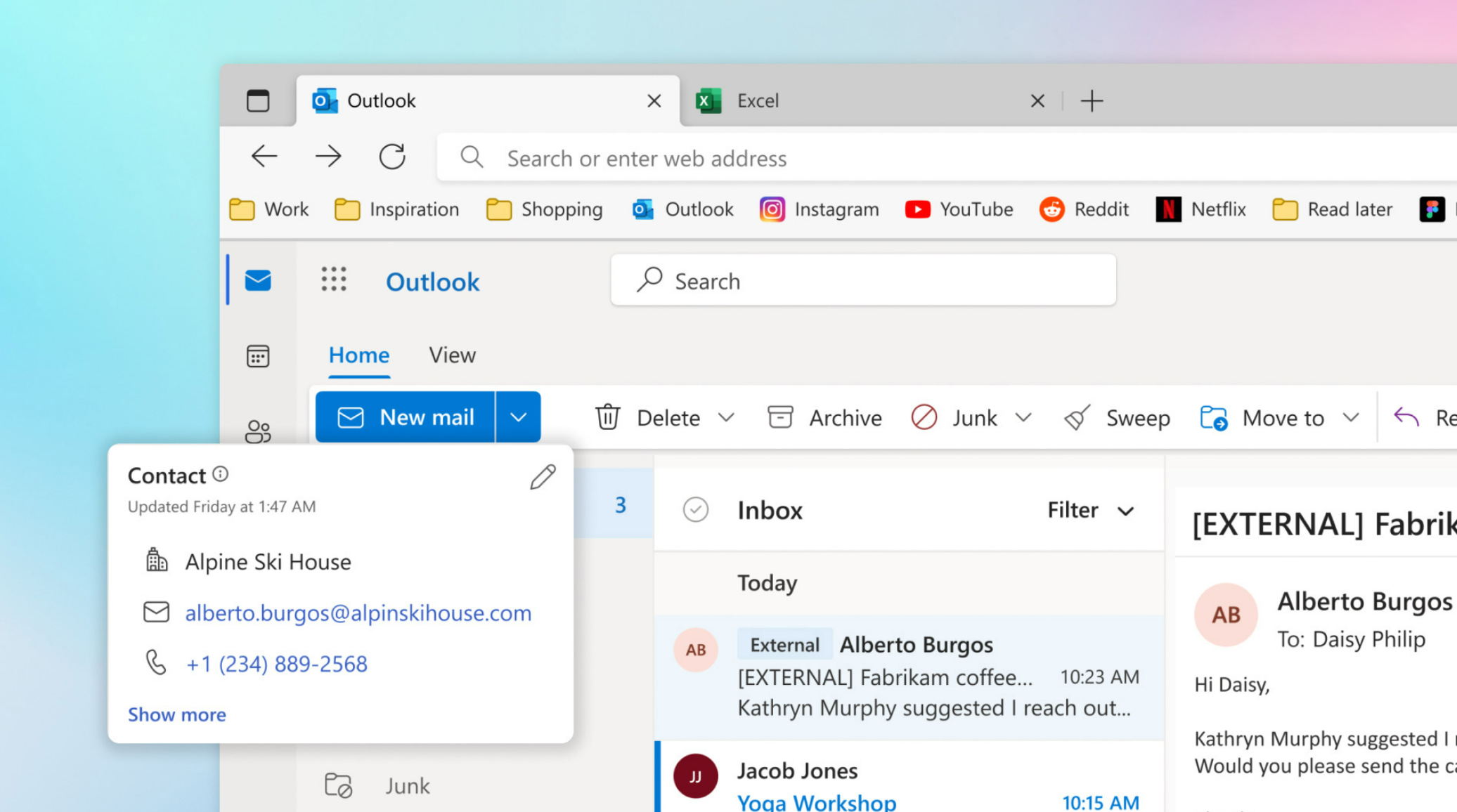

Euwe Eugen Wexler de México is a leading company in the Plastic Injection Industry, which was established in Mexico in 1993, with a primary focus on the production of automotive auto parts. The company needed to have an ERP-type business administration system that would allow it to integrate production information, inventory control, logistics, as well as financial-administrative data in a single platform, with a reliable and reliable database. consolidated. After a process of searching and analyzing different alternatives on the market, it was decided on the Microsoft Dynamics 365 solution, which made it possible to cover all the established improvement points and the objective that this system could grow at the pace of the company.

The main objective is to maintain a sustainable competitive advantage, optimizing business processes thanks to the use of technology.

Due to this, the planning horizons had to be carried out in the short term and it was complicated to have data for decision making. Therefore, they considered that this work environment should be optimized through a solid base of operations

Technological Challenge

Main Benefits

The object-based development tools and the flexibility offered by Microsoft Dynamics 365 allowed Euwe to make the adaptations at those points that require customization.

START YOUR DIGITAL TRANSFORMATION HERE

COMMUNITY

Consult blog articles and answer your questions immediately

Visit BLOG >

CONTACT

Request that we contact you. A Dynamics 365 expert will be in touch to advise you.